I got a chance over the summer to visit the fully converted stone barn that we designed in Gabillou, in south-west France.

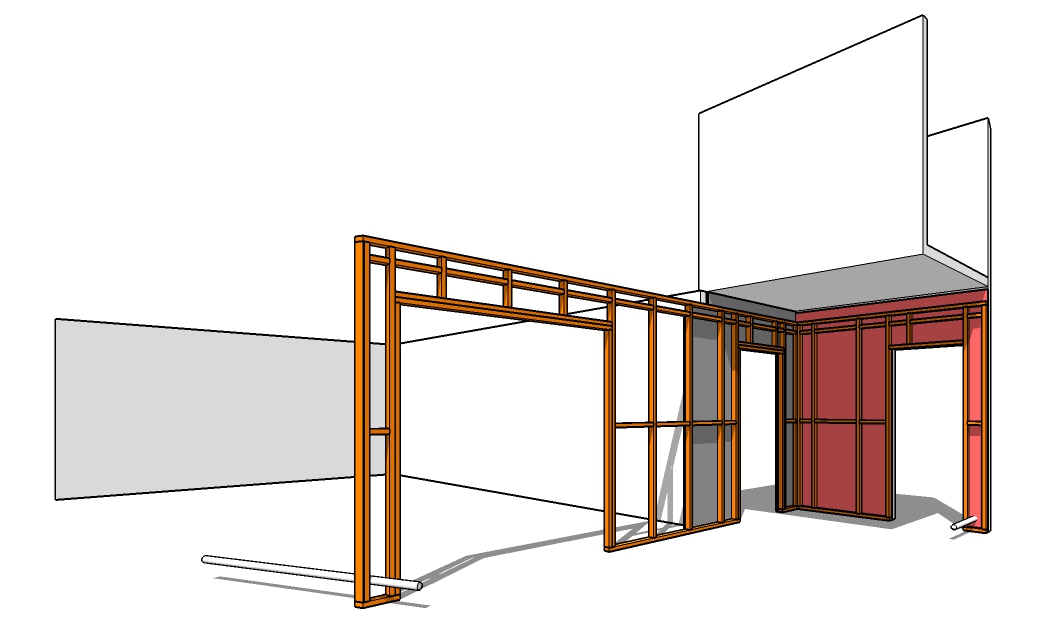

This 19th century agricultural building was transformed into a stunning home between 2007 and 2018, by our self-builder clients themselves, who lived in the building over the course of the conversion process, thanks to our phased construction design approach.

With an amazing attention to detail and a lot of enthusiasm, the couple has now become expert self-builders and joiners, already looking forward to a new conversion project to use their skills!

Below is a collection of pictures I took of the finished barn this August.

Looking down at the half-floor lounge from the upper floor

Looking up the lightwell from the living-room

The new wall opening to the garden, from the living-room

Stairs up to the half-floor lounge, and down to the guest suite, from the living-room

Glass railing detail from the lounge

Looking toward the kitchen and upper floor, from the lounge

The lounge

The kitchen and upper floor, from the lounge

Roof over the lounge

Detail of the lime mortar pointing of the stone wall

Looking up the south gable, from the lounge

The historical timber structure, supporting the new roof, insulated with wood fiber

Custom staircase, built by our clients

Looking up the staircase to the upper floor

Home office on the sunken landing of the upper floor

View from the master bedroom, past the light well over the children's bedrooms

Looking up from one of the children's bedroom

South gable, with the new opening to the lounge

South east corner of the barn

Lavender along the south gable

Outside details of the workshop door

South east corner, with the separate entrance to the guest suite

New workshop door

The entrance door

Detail of the guest suite entrance

The main terrace to the east, with the new openings

Aerial view of the barn

Photo © Béranger Devuder-Hau